What Factors Determine the Maximum Flow Rate of a Centrifugal Pump?

- By Matt Beckerdite

- Mar 25, 2025

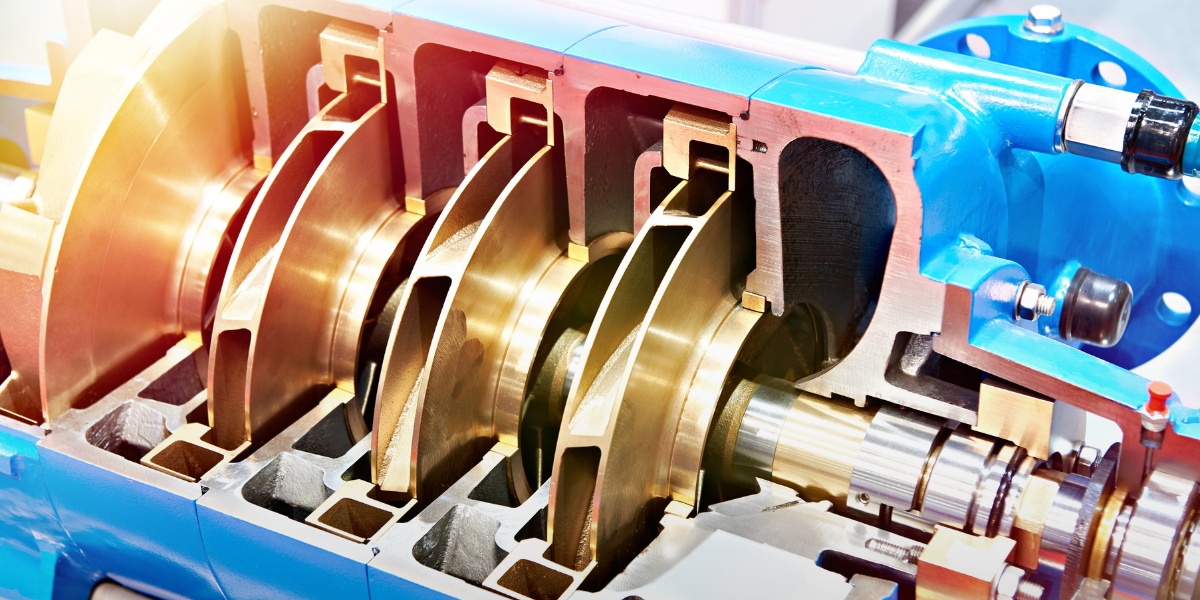

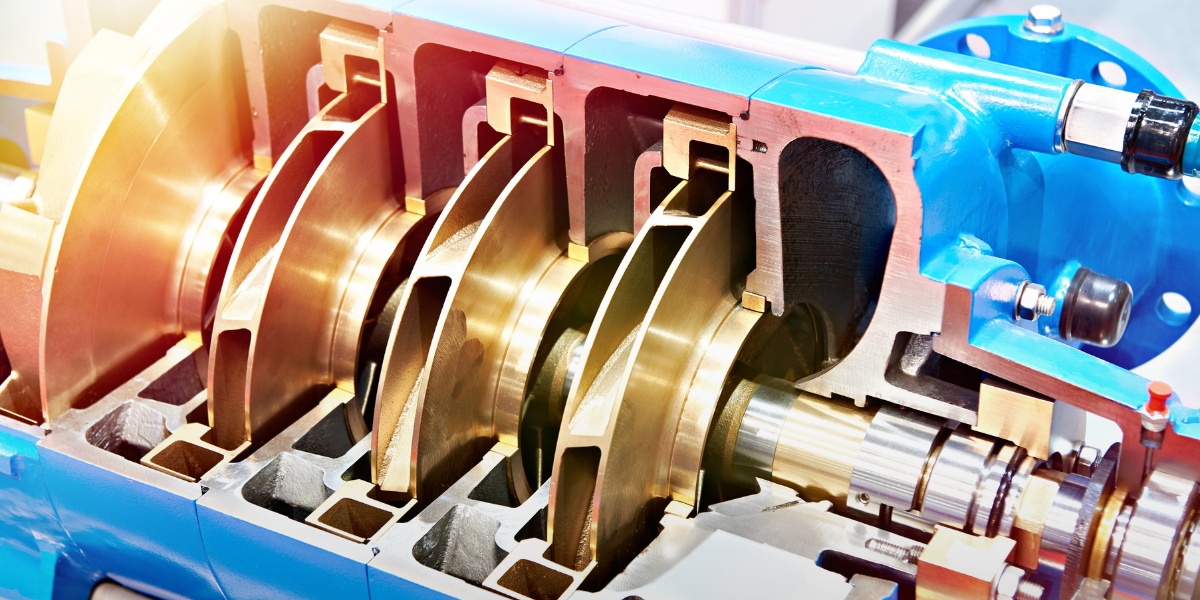

Centrifugal pumps move liquids in industrial, commercial, and municipal applications. But what determines how much fluid a pump can move? The maximum flow rate isn’t only about the pump itself; it depends on several factors.

8 Factors Impacting Centrifugal Pump Flow Rate

Ever wonder what’s really limiting your pump’s flow rate? Knowing these details helps you get the most out of your system.

1. Impeller Design

The impeller plays a major role in flow rate. Its design, size, and vane configuration affect how much liquid the pump moves.

- Larger impeller vanes generate higher flow rates by displacing more liquid with each rotation.

- Larger impeller diameters generate higher pressures by increasing the tip speed, which imparts more kinetic energy to the fluid, resulting in greater conversion to pressure head within the pump.

- Curved vanes improve efficiency by reducing turbulence, while straight vanes handle solids better but may slightly reduce efficiency.

- More vanes can improve efficiency in clean low-viscosity fluids but may reduce the pump’s ability to move debris or viscous liquids due to tighter flow passages.

However, bigger and faster isn’t always better. Selecting an impeller that is too large or aggressive for the system can lead to unnecessary energy use or excessive wear over time. A well-matched impeller design for actual operating conditions often works better than maximizing size and speed.

2. Pump Speed (RPM)

The rotational speed of the impeller (measured in RPM) affects the flow rate according to pump affinity laws, but system resistance may limit actual gains in flow. The faster it spins, the more liquid it moves.

However, increasing speed isn’t always beneficial. Higher RPM increases flow rate, but exceeding recommended limits can cause excessive wear, overheating, or even pump failure.

Expert Tip: Variable-frequency drives can help fine-tune speed, but they are not a universal fix. If your system is poorly designed, a VFD may not solve efficiency issues.

3. Suction Conditions

Poor suction conditions can reduce a pump’s ability to move fluid. To maintain flow:

- Keep the suction line clear and free of obstructions.

- Ensure the inlet is submerged to prevent air entrainment.

- Ensure that Net Positive Suction Head Available (NPSHa) is always higher than the pump’s required NPSHr to prevent cavitation, which can damage the impeller and reduce efficiency.

- Use an adequately sized suction pipe to minimize friction losses.

Despite manufacturers’ claims, real-world suction conditions are rarely ideal. System design flaws, like poorly placed inlets or air leaks, often cause bigger performance issues than the pump itself. Addressing these external factors first can sometimes improve performance more than upgrading the centrifugal pump.

Expert Tip: A filter on the suction side will help prevent solids and debris from entering the pump. However, we recommend you maintain 5–10 pipe diameters of straight pipe between the filter and the pump suction inlet. Rule of Thumb: Don’t allow more than 1–2 psi pressure drop across the suction filter, especially in low-NPSHa systems.

4. Discharge Pressure

Pump flow rate and discharge pressure have an inverse relationship: the higher the pressure required at the outlet, the lower the achievable flow rate. If the system demands high pressure, the pump has to work harder, potentially reducing efficiency. Reducing unnecessary restrictions in the discharge piping, such as excess valves and sharp bends, can help maintain flow.

Some operators mistakenly assume that increasing discharge pressure is necessary for better performance. In reality, many systems suffer from excessive pressure demands due to poor piping design rather than actual operational needs. Reevaluating system pressure requirements can sometimes improve efficiency without requiring a more powerful pump.

5. Fluid Characteristics

The type of liquid being pumped affects flow rate.

- Viscosity: Thicker fluids (like oil or syrup) move more slowly than water and require more power to pump at the same flow rate. Tip: For pumping viscous fluids, consider lowering RPM rather than increasing motor power to prevent excessive wear on the impeller.

- Temperature: Fluids with extreme temperatures can change viscosity, affecting how easily they flow.

- Specific Gravity: Heavier liquids exert more pressure on the pump, influencing how much volume can be moved and how much motor horsepower is required.

6. Pipe Size & Length

The size and length of the piping system also affect pump flow rate.

- Narrow pipes create friction, reducing the pump’s ability to move fluid efficiently.

- Long pipe runs add resistance, further limiting the achievable flow.

- Sharp bends and fittings introduce turbulence, increasing energy losses.

Instead of defaulting to a larger pump, many experts argue that modifying piping size and layout can achieve better results at a lower cost.

7. System Design

A poorly designed system can restrict flow even if the pump itself is capable of high performance. Obstructive bends, tight valves, and improperly sized pump components create resistance that can reduce efficiency. Many flow limitations come from the broader system, not the pump itself. Total Dynamic Head (TDH), including friction loss and system resistance, plays a significant role in determining actual pump performance.

8. Pump Efficiency & Wear Over Time

Even a properly designed system can experience flow rate reductions due to wear and tear. Over time, impeller erosion, scaling, and corrosion inside the pump and pipes, as well as seal and bearing wear, can increase internal resistance and reduce efficiency.

Expert Tip: Regularly inspect and clean impellers, as mineral deposits and debris buildup can drastically reduce performance over time.

Find the Right Pump with American Stainless Pumps

American Stainless Pumps offers high-quality centrifugal pumps designed for efficiency and durability. Our stainless steel pumps are built to handle a range of industrial and commercial applications, ensuring reliability and long-term performance.

Contact us today to learn more about ASP.